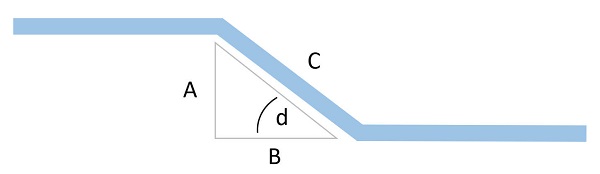

The black line represents an offset bend in a tube the red triangle represents the triangular geometry this offset creates. Most bends other than 90° can be calculated using the geometry of a triangle. Then, use this formula:įor example, if your die creates a 2.2” radius, and you need to create a 35° bend, your calculations would look something like this: Using the same variables as above, the standard dimension ratio (SDR) of a pipe can be calculated thusly:Ĭalculating CLR (Center Line Radius) for Bend AngleĪfter you’ve selected the appropriate die for bending your pipe, based on the pipe’s outside diameter and wall thickness, you should be able to find the radius of the bend.Ī simple way to determine the center line radius of a bend of a specific angle is calculate a full circle, then divide that number by 360 to find the measurement of one degree. S = wall thickness (mm) | S = pipe serial (-) Σ s = hoop stress (N/mm 2) | PN = normal pressure (bar) | da = external pipe diameter (mm) ISO 161-1 uses the following formula to calculate the wall thickness of pipe: It is important to understand the different elements of a bend in order to make accurate calculations. This radius will vary depending on the outside diameter of the tube, the wall thickness, and the angle at which the tube is to be bent. When calculating bend allowances to determine the cut length of HDPE conduit or PVC pipe, one must calculate from the center line radius (CLR) of the finished, bent pipe. An inexpensive scientific calculator and an angle finder are the only additional tools required. Using just a few mathematical formulas allows you to properly calculate a bend of nearly any angle.

0 kommentar(er)

0 kommentar(er)